Machines & lines for sandwich bread

Sandwich bread is a type of bread, sweet or not, which is characterised by its lack of a crisp crust and the softness of its crumb, which appears very white.

Rye bread is one of the special breads in that it is made mainly with rye flour. This bread is also called "black bread". The proportion of rye flour in the dough must be at least 65% for the bread to be marketed under this term, if the rate is between 10 and 35%, the bread is called "rye bread".

The DIVA divider allows cutting the dough into 20 dough pieces of up to 1 kg each, to be shaped afterwards. This model has a square tank.

Dough pieces from 150g to 1 000g.

The DIVA divider allows cutting the dough into 20 dough pieces of up to 1 kg each, to be shaped afterwards. This model has a round tank.

Dough pieces from 150g to 1 000g.

In addition to dividing 20 dough pieces up to 1 kg each, the Div'X can also divide pre-fermented dough, thanks to the adaptable grids available in the catalog. We therefore obtain ready-to-bake dough pieces, in different shapes, such as traditional breads, rustic bread, ciabatta, rolls, etc.

The Atoupains offers all the versatility of classic divider-shaper. Above all, it has built its reputation in the market thanks to the quality of the baguettes that it allows to obtain thanks to the AlveoForm system. No more slicing marks, it's time for beautiful, well-shaped baguettes, with round or square ends!

Same as Div'X GOLD + connected machine

The Div-Smart offers a connected solution, allowing you among others to save the recipe parameters or to export daily production reports. Alerts to assist you in cleaning and maintenance operations to increase machine longevity.

Designed on the same basis as the Div-Smart divider-shaper, this new automatic and connected machine can also produce 10 baguettes in 10 seconds, without using the grid holder, after having simply closed the lid (50% less handling). In addition, thanks to the AlvéoForm tray, no need to transfer the dough pieces twice before placing in the oven!

Armor moulders allow better respect for the dough thanks to their dough extension on a fixed table, thus reproducing manual shaping for optimal results.

Up to 1 800 pieces/h.

Dough pieces from 50g to 2 000g.

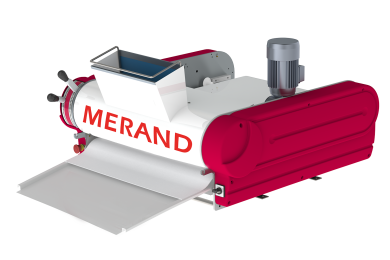

For decades, the Tregor model has built MERAND's reputation around the world. Economical, reliable and efficient, this moulder is the best-seller of the range. Up to 1 800 pieces/h. Dough pieces from 50g to 1 450g.

The Lofty divider can automatically divide dough pieces for breads and baguettes from 1 000 to 2 400 pieces/h. Its hopper with a capacity of approximately 200kg of dough gives the possibility of pouring a complete kneader into it. It is the basis of most MERAND automatic groups.

The Softy divider can ensure high dividing rates, up to 2700 pieces/h. Its robustness and reliability make it the perfect divider for feeding semi-industrial production lines.

Automatic division of blocks of dough to feed, in particular, divider-shapers, ciabatta machines, etc. This avoids laborious devatting and weighing operations, while increasing productivity.

Up to 2 400 dough pieces/h.

In addition to producing blocks of dough to feed, in particular, divider-shapers, ciabatta machines,... the Divbloc Dual can also feed the intermediate proofer of your automatic group. One machine for 2 functions, save space and increase productivity!

Up to 2 400 dough pieces/h.

The Mecaform Industry is the first choice proofer for MERAND semi-automatic bread lines to get increased productivity. Its different systems improve the regularity and quality of the final products.

Up to 672 pockets in total.

Dough pieces up to 900g max.

The BMF Mécaform has a special dough piece loader that can load pre-extended dough pieces.

Up to 490 pockets in total.

Dough pieces up to 1 000gr max.

Intermediate proofer with a larger capacity than a manual proofer. Automatic emptying in the moulder is located inside the proofer, allowing a higher volume of production in a limited space.

70 swing trays max.

Dough pieces up to 900g max.

Intermediate proofer with a larger capacity than a manual proofer. Automatic emptying in the moulder is located outside the proofer, allowing a higher volume of production.

70 swing trays max.

Dough pieces up to 900g max.

Thanks to its automatic loading and emptying the BMF ensures a high production rates and minimize operator handling. The moulder is situated inside the proofer.

Up to 560 pockets in total.

Dough pieces up to 1000g max.

Thanks to its automatic loading and emptying the BMF ensures a high production rates and minimize operator handling. The moulder is situated outside the proofer.

Up to 560 pockets in total.

Dough pieces up to 1000g max.

Unlike other proofers of the MERAND range, the DynaProof gives the dough pieces a "dynamic" rest. Meaning that the dough pieces change pockets between each resting cycle, which is ideal for giving dough the strength and having a tighter crumb (sandwich loaves,...).

Up to 621 pockets in total.

Dough pieces up to 1 000g max.

In the case of the BMF Compact, the shaper is inside the swing (both vertical and horizontal shapers). In the case of the BMF Leader, the shaper is outside and can be placed on a long receiving belt.

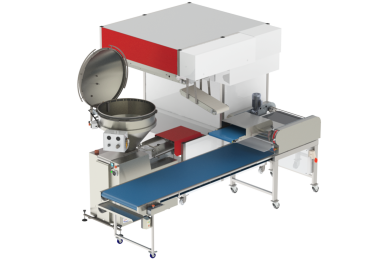

The KraftLine range of machines is particularly suitable for the production of large round and elongated but rather short dough pieces. The production volume of the KraftLine 2.0 is 2 000 dough pieces/h

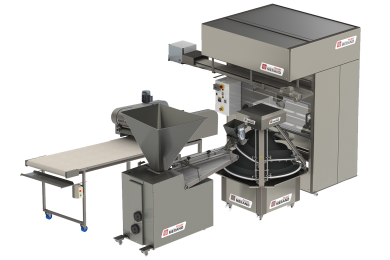

The KraftLine range of machines is particularly suitable for production of large round and elongated but rather short dough pieces. The output of the KraftLine 2.5 is up to 2 500 dough pieces/h.

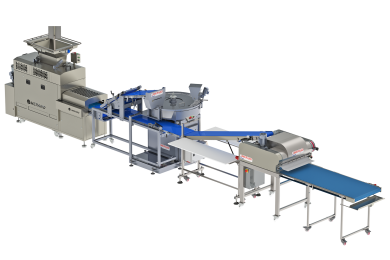

The range of machines that make up the RheoPan System makes it possible to produce a wide variety of products with different types of dough without any stress and with very good precision in the weights.