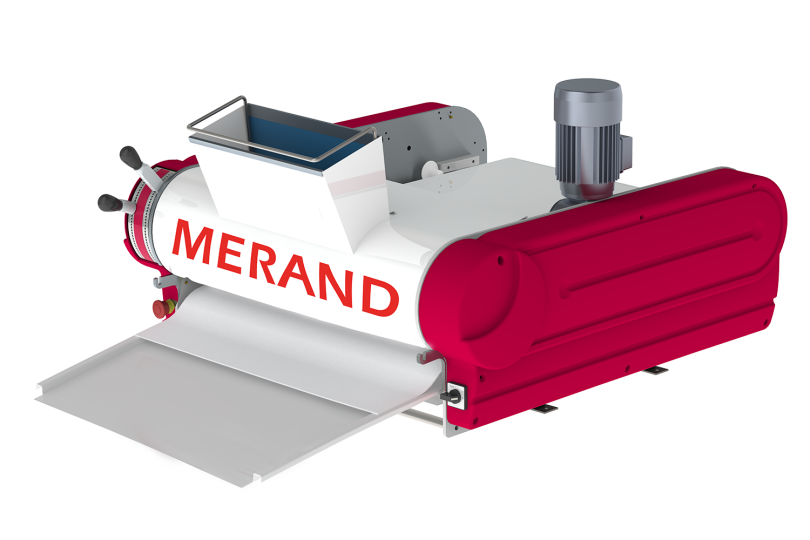

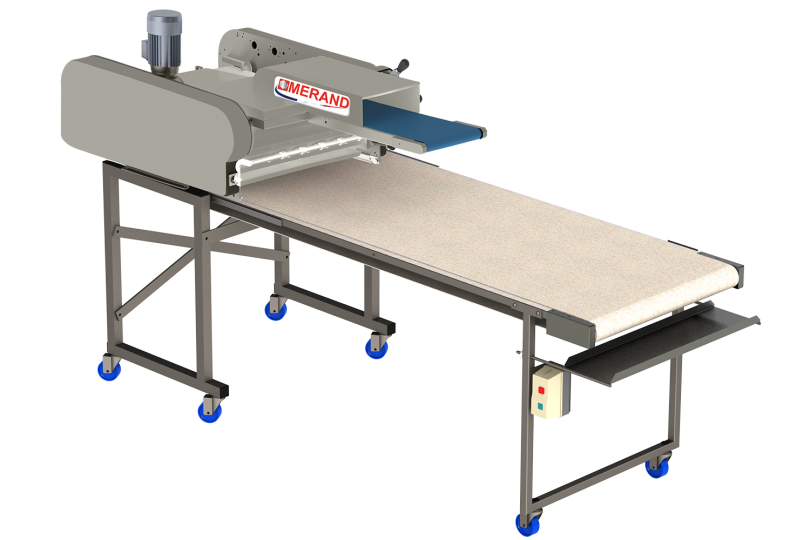

Armor horizontal moulder

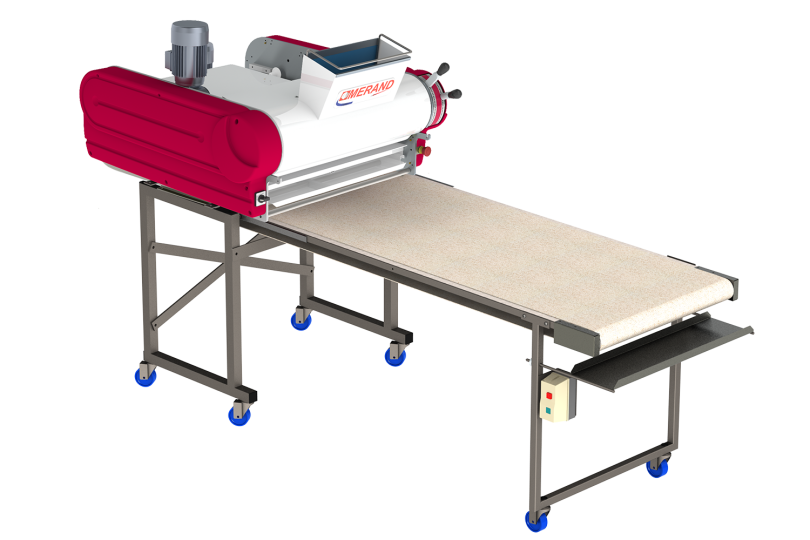

The Armor horizontal moulder is comparable in terms of operation and respect for the dough to those manufactured by MERAND in 1954, at the beginning of mechanical shaping in France. With its extension on a fixed table, it reproduces manual shaping, as on a work surface. Ideal for shaping Traditional baguettes or fragile doughs because it does not heat up the dough.

Its 2-step lengthening system will allow you to lengthen your baguettes to the desired length, without having to touch them up manually.

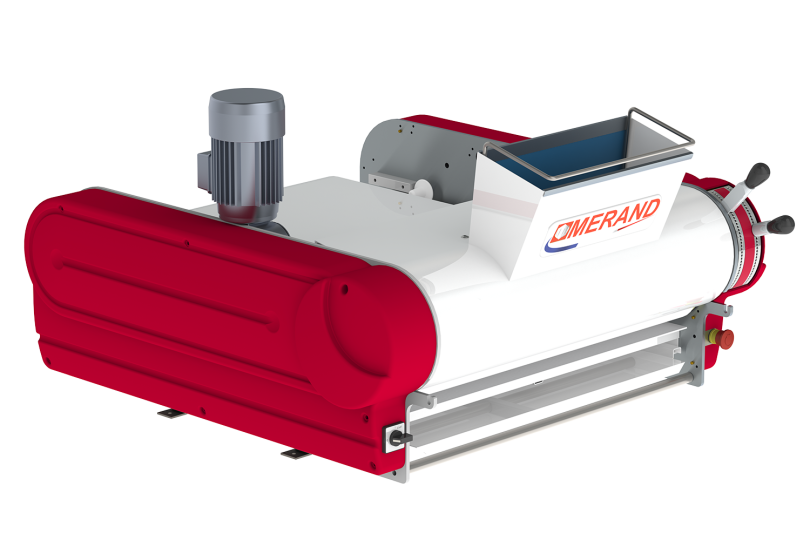

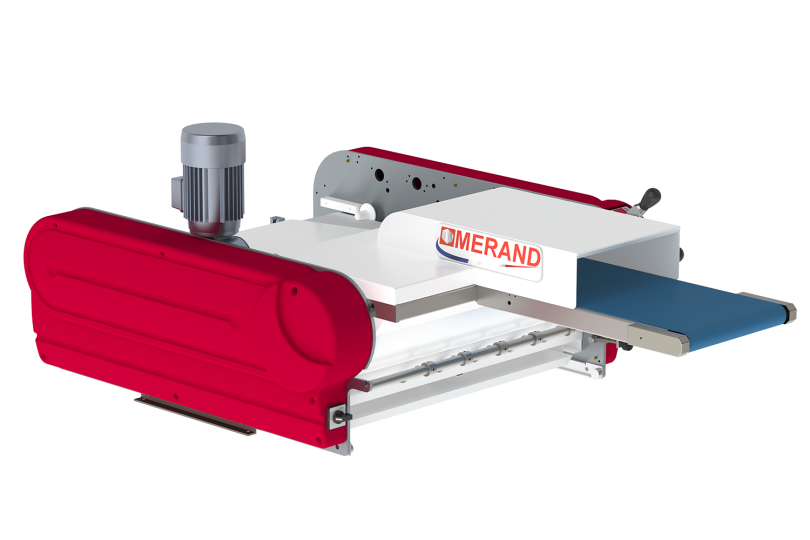

The Armor horizontal moulder in the Tradition version is equipped with the Alvéo+ system, where the manual pre-laminating roller has small cells similar to manual laminating. This system will allow you to avoid degassing your dough, even the most fragile.

The Pointop, an accessory also available in the Tradition version, will give you beautiful baguettes with pointed ends, shaped automatically, in order to diversify your breads.

Basic features :

-

Up to 1 800 dough pieces per hour (depending on weight and dough type)

-

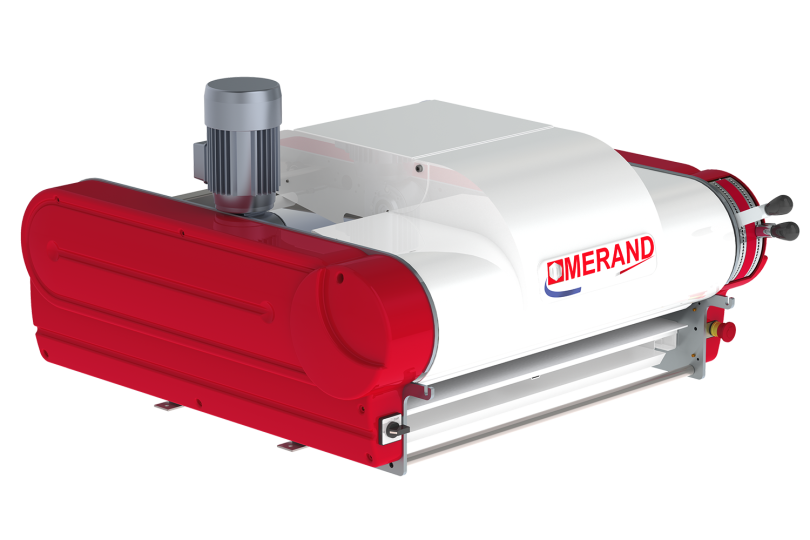

2 selectors with pointers to adjust the rolling and the lengthening (more accurate and faster than a clamping screw)

-

Guarantee a very low noise level while operating

-

Dough lengthening between the driven belt and a fixed table reproducing manual shaping

-

1 laminating roller + 1 pre-lamination roller

-

7mm thick felt for optimized shaping

-

Dough pieces weights from 50g to 2 000g

-

2 lengthening phases for smooth stretching of dough without tearing it up and an improved regularity

Armor Tradition :

-

Rolling system Alvéo+: roll with honeycomb surface to prevent dough outgassing

-

Pointop: accessory for breads with pointed ends

|

Armor ABS II |

Armor Tradition |

|

|

Basic features |

✔ |

✔ |

|

Alvéo+ |

✔ |

|

|

Pointop |

✔ |