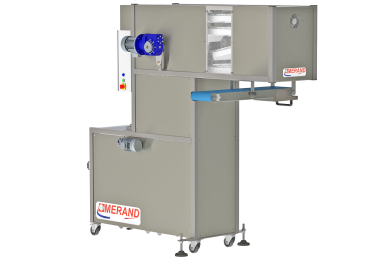

Compact PAGE semi-automatic proofer

Intermediate proofer with a larger capacity than a manual proofer. Automatic emptying in the moulder is located inside the proofer, allowing a higher volume of production in a limited space.

70 swing trays max.

Dough pieces up to 900g max.