Machines & lines for brioche

Brioche dough has the characteristics of yeast doughs, but its difference from other yeast doughs is that it contains a lot of eggs (minimum 6 eggs/kg of flour). The intrinsic richness of this dough requires the use of flour rich in protein (gluten), in order to ensure the correct structuring of the products. In addition to fermentation, the final quality of the products depends on the quality of the fat used (butter), and the egg content.

The Atoupains offers all the versatility of classic divider-shaper. Above all, it has built its reputation in the market thanks to the quality of the baguettes that it allows to obtain thanks to the AlveoForm system. No more slicing marks, it's time for beautiful, well-shaped baguettes, with round or square ends!

Designed on the same basis as the Div-Smart divider-shaper, this new automatic and connected machine can also produce 10 baguettes in 10 seconds, without using the grid holder, after having simply closed the lid (50% less handling). In addition, thanks to the AlvéoForm tray, no need to transfer the dough pieces twice before placing in the oven!

The Lofty divider can automatically divide dough pieces for breads and baguettes from 1 000 to 2 400 pieces/h. Its hopper with a capacity of approximately 200kg of dough gives the possibility of pouring a complete kneader into it. It is the basis of most MERAND automatic groups.

The Softy divider can ensure high dividing rates, up to 2700 pieces/h. Its robustness and reliability make it the perfect divider for feeding semi-industrial production lines.

Automatic division of blocks of dough to feed, in particular, divider-shapers, ciabatta machines, etc. This avoids laborious devatting and weighing operations, while increasing productivity.

Up to 2 400 dough pieces/h.

In addition to producing blocks of dough to feed, in particular, divider-shapers, ciabatta machines,... the Divbloc Dual can also feed the intermediate proofer of your automatic group. One machine for 2 functions, save space and increase productivity!

Up to 2 400 dough pieces/h.

The RheoPan Precision automatic divider is the head of the RheoPan line. Thanks to the weighing of the dough pieces and the automatic adjustment of the settings, it divides with great precision of weight, and without stress, both strongly hydrated and/or fermented doughs as well as hard doughs.

Up to 850kg/dough/h max (depending on model).

The Armor HV horizontal moulder includes all the features of the Armor Tradition model, but also is reinforced to keep higher daily rates. The included Tradition Pack will allow you to limit the degassing of your dough.

Up to 1 800 pieces/h. Dough pieces from 50g to 2000g.

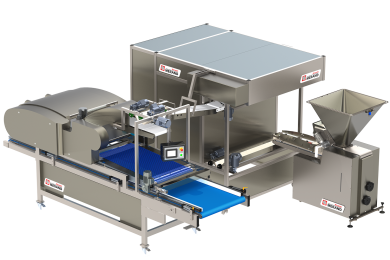

Automatic line particularly recommended for the production of Tradition and white baguettes (and a wide range of other breads).

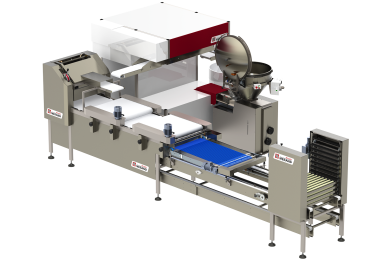

The range of machines that make up the RheoPan makes it possible to produce a wide variety of products with different types of dough without any stress and with very good precision in the weights.

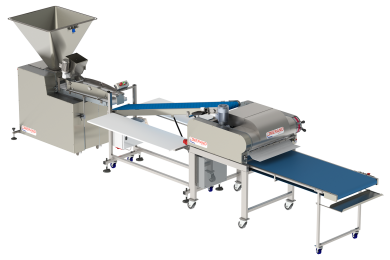

Particularly recommended for the production of baguettes and rolls, the production volume of the FlexiLine 1.5 is approximately 1 500 baguettes or rolls per hour.

Particularly suitable for the production of long baguettes (without damaging the dough) and for cutting into small loaves thanks to the various exclusive systems.

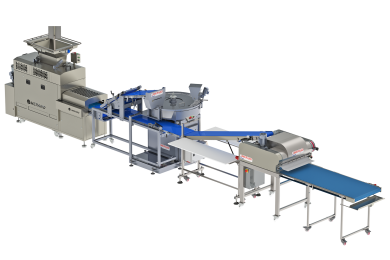

Particularly suitable for the production of baguettes and rolls, this line can produce up to 2 500 baguettes/hour, for a daily production of about 50 000 baguettes.