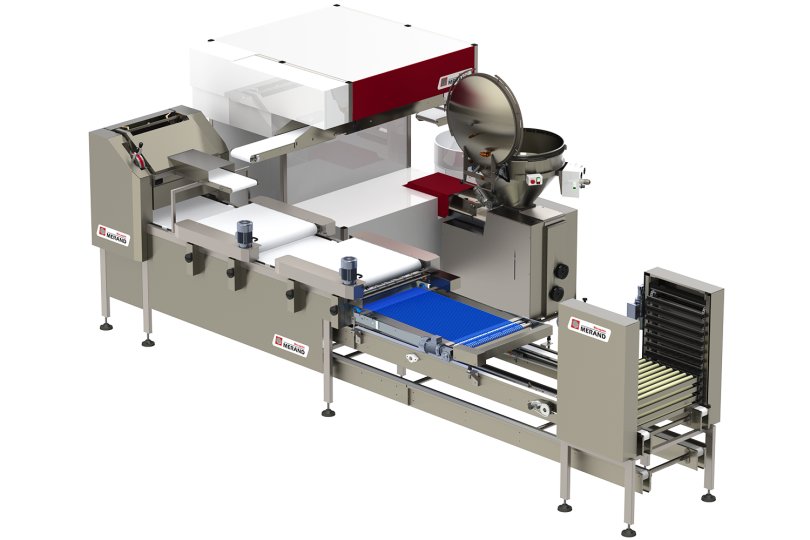

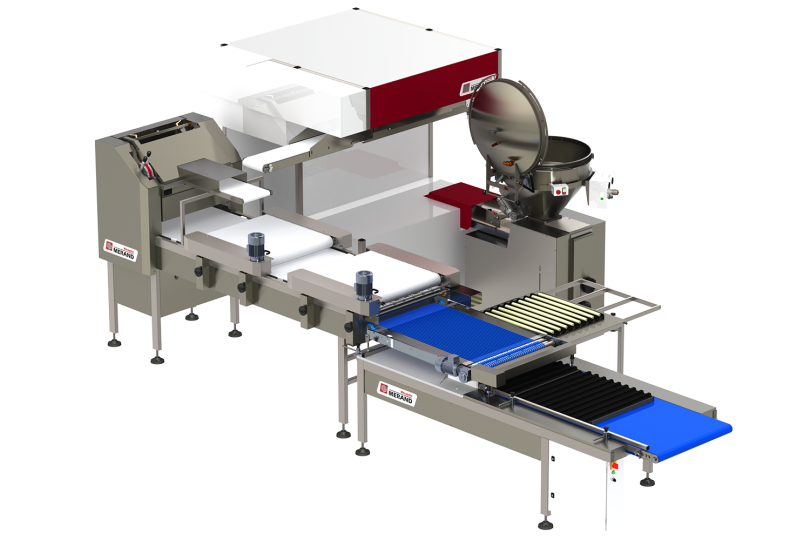

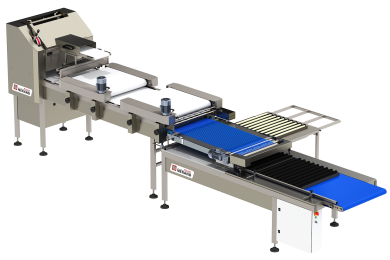

FlexiLine 1.8 automatic line

The automatic line for baguettes and rolls. FlexiLine 1.8 can divide and shape baguettes and rolls at a rate of 1 800 baguettes/hour and 6 000 rolls/hour, with the greatest respect for the dough and the baking tradition.

In order to obtain a good regularity of the baguettes, without stress for the dough, the stretching is done in 4 stages with rest and release of the dough pieces between each shaping stage. The FlexiLine 1.8 semi-industrial line for baguettes and rolls is connected to an automatic net depositor.

This not only improves productivity but also the quality of the shaped baguettes and rolls as the operators do not touch the products. A spacing system for the rolls before automatic depositing prevents the rolls from touching each other during the proofing process.

-

The versatility of the automatic line as it can produce a whole range of breads, thanks to accessories that can be simply slid into the shaping line. For example, baguettes with pointed ends, bread in a mould, sandwich bread, small breads, 1/2 baguettes, sticks, special breads, large breads...

-

Automatic cutting of baguettes into 1/2 baguettes, 1/3 baguettes, 1/4 baguettes and buns, without trimming and without shrinkage as the baguettes are cut while still in the shaper.

-

The scalability of the line is an important element in the investment of an automatic baguette and bread production line. It is possible to add to the automatic line, only when the needs arise and justify the investment. This is particularly the case for the addition of the automatic net depositor, but also the net accumulator in order to increase the productivity of the automatic line, while reducing labour costs.