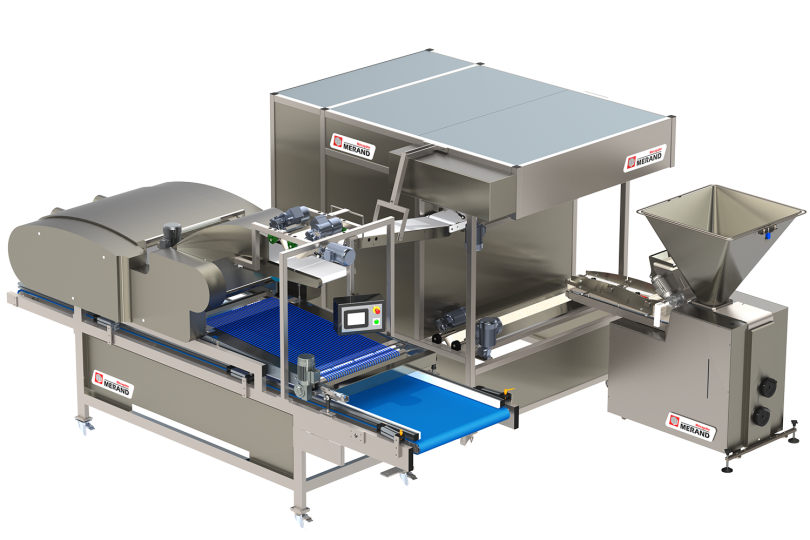

FlexiLine 2.5 automatic line

The FlexiLine 2.5 automatic bread line has an output of approximately 2 500 baguettes or loaves per hour.

It is recommended for use from 16 to 24 hours per day. The FlexLine 2.5 version is particularly suitable for the production of small loaves.

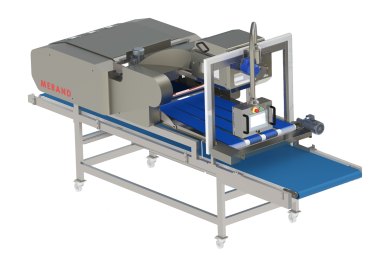

It has a particularly efficient dough piece centering system, the Top-Centering. The Top-Centering system measures the length of the pre-rolled dough pieces at the exit of the Macaform VE Industrie expansion chamber and positions the middle of the dough piece in the middle of the infeed belt into the moulder.

Different configurations are possible depending on the requirements. For example, the Proform shaper can be installed on an automatic net depositor of the I-Deposit or DF-Elevator type.

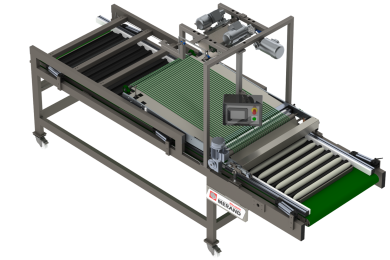

These automatic net feeders are equipped with a spreader system for the cut rolls so that they are separated before being fed into the net. The Mecaform expansion chamber can also be used to feed a second shaper (Kraft 2.5 for sandwich breads) or, more often, an eccentric rounder such as RotaBall or RollerDual.

The RollScoup option cuts baguettes into 1/2, 1/3, 1/4, 1/5, 1/6 sizes for regular production of rolls.