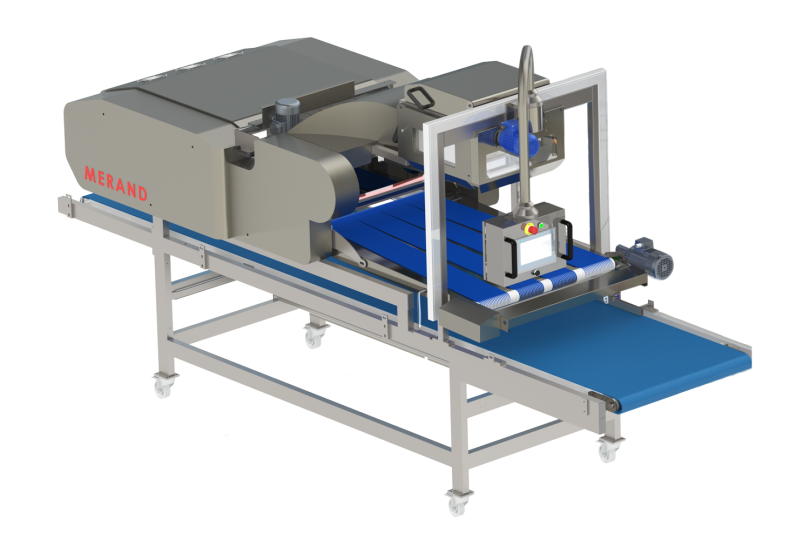

Proform semi-industrial moulder

Proform moulder is equipped with the exclusive C2A (Assisted Elongation Control) system. Thanks to its 2 belts with speed variation, it allows 3 types of operation depending on the type of bread being shaped :

- Lower belt stopped: for traditional baguettes or breads with pointed ends (identical to the shapers with lengthening on fixed table).

- Bottom conveyor belt moving backwards: for very long baguettes and for optimal rolls cutting.

- Bottom conveyor belt moving forward: for short loaves, baguettes, specialty breads...

Coupled with the dough piece centering machine between the expansion chamber and the feed belt of the shaper, the Proform is particularly suitable for the use of the RollsCoup system for large productions of small loaves (1/2, 1/3, 1/4, 1/5 of baguettes).

It is equipped with a touch panel that allows to centralize all the line settings and to memorize them according to the different recipes.

The Proform moulder can produce up to 2 500 dough pieces/hour for 22 hours/day. To optimise productivity, the Proform is usually connected to the automatic tray deposit system and tray loader/unloader.