FlexiLine

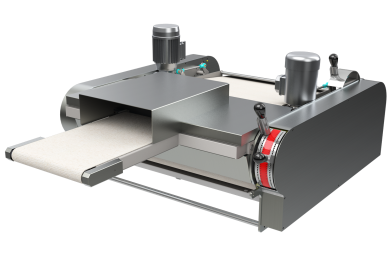

Automatic Flexiline 1.5

Particularly recommended for the production of baguettes and rolls, the production volume of the FlexiLine 1.5 is approximately 1 500 baguettes or rolls per hour.

The FlexiLine 1.5 automatic line has an output of approximately 1 500 baguettes or loaves per hour.

It is recommended for a daily operation of about 8 to 10 hours. Différent configurations are possible depending on the requirements.

For example, the Armor HV shaper can be placed on a reception belt for the shaped dough pieces or on an automatic L-shaped deposit net.

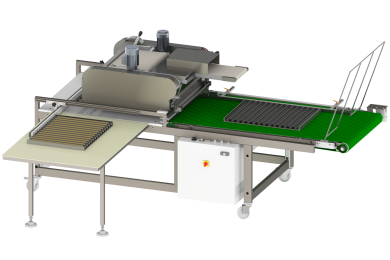

It is also possible, from the Mecaform expansion chamber, to feed a second shaper (of the Kraft 2.0 type for sandwich loaves, for example) or more often an eccentric rounder of the RotaBall or RollerDual type.

The RollScoup option, a baguette cutting system, can be adapted for occasional production of rolls.