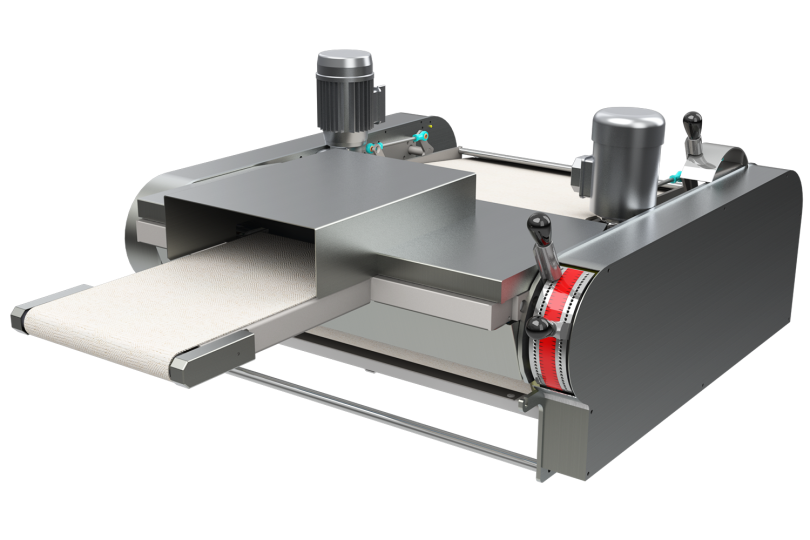

Armor Allonge+ horizontal moulder

The moulder ARMOR Allonge Plus is similar in terms of operation and respect of the dough to those manufactured by MERAND from 1954, at the beginning of mechanical shaping in France.

With its lower lengthening on a fixed table, it reproduces manual shaping while avoiding the dough heating. Its 2-step progressive lengthening prevents tearing of the dough pieces. Its motorized upper lengthening will help you lengthen your baguettes to the desired length, without having to manually adjust them. It is equipped with the Alvéo+ system: the laminating roller has small alveolus (similar to a golf ball), reproducing a manual rolling.

This system prevents outgassing of doughs, even the most fragile ones. The Armor Allonge Plus can hold higher daily rates thanks to its structure and mechanisms more robust than an artisanal moulder. Its stainless steel casing improves its lifespan.

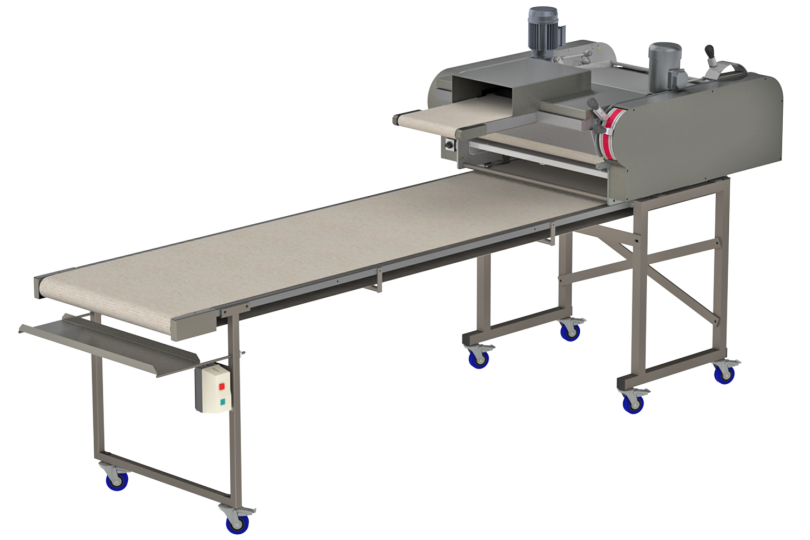

- Up to 1 800 dough pieces per hour (depending on weight and dough type)

- 3 of needle selectors for setting the rolling and the extensions (more accurate and faster than a clamping screw)

- Guaranteed very low level of sound in operation

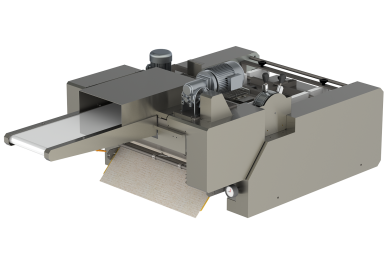

- Lengthening between a belt and a fixed table reproducing manual shaping

- 1 laminating roller + 1 Alvéo+ pre-laminating roller

- 7 mm thick felt for optimized shaping

- Dough pieces: from 50g to 2 000g

- Controls located on the right side (optional on the left side).

- Stainless steel casing

- 2 shaping phases for more length without dough tearing and better regularity

- Alvéo+ pre-rolling system: roll with a honeycomb surface to prevent outgassing

- Reinforced sprockets in case-hardened steel for an optimal life span

- Upper lengthening under motorized inverted belt, for optimum lengthening