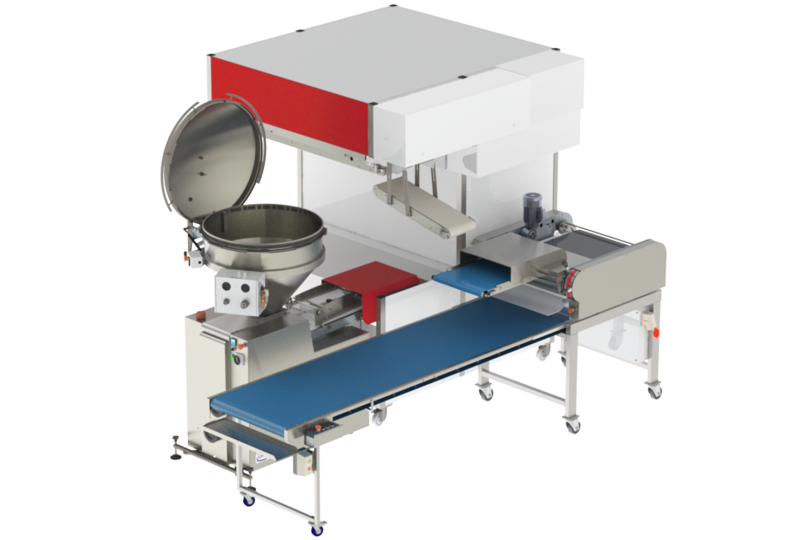

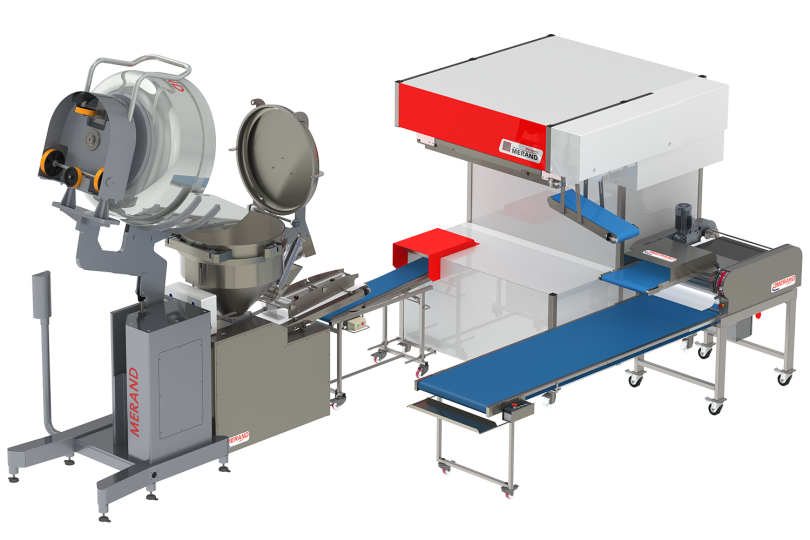

BMF automatic group (Compact & Leader)

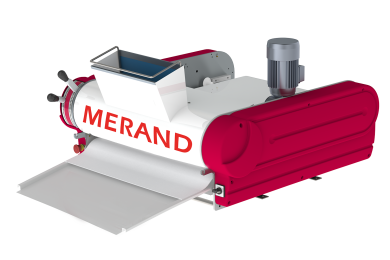

The BMF Compact and Leader automatic group process pre-rolled dough pieces on the divider-weigher, as in the case of the DynaProof group.

The only difference is in the type of scale. In contrast to the DynaProof model, wich is a "dynamic" model, the BMF models are "static" type of scales. This means that the dough pieces remain in the same pocket between loading and emptying.

This optimises the relaxation of the dough pieces and promotes stretching in the shaper. There is a dough piece loader-repairer to place the dough pieces in the pockets.

The welded 50x50mm stainless steel tube structure ensures high rigidity of the frame. The cover is made of Dibon panels to facilitate cleaning and maintenance of the machine.

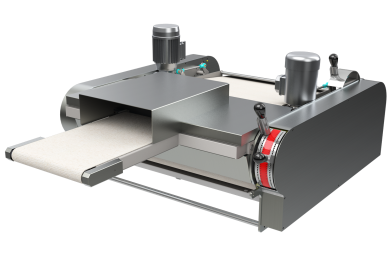

In the case of the BMF Compact, the shaper is inside the swing (both vertical and horizontal shapers). In the case of the BMF Leader, the shaper is outside and can be placed on a long receiving belt.

As an option, a double transfer belt can be installed to feed 2 machines after emptying (one shaper and one eccentric rounder).

The pockets are made of Nyltex for better hygiene and easier cleaning. Several versions are available depending on the number of pockets required and the maximum weight of the dough pieces.