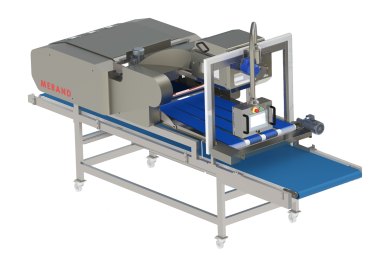

EasyLine automatic line

In most cases, it is recommended to leave a certain amount of time for the dough pieces to relax between dividing and shaping, especially for long products such as baguettes. However, in some situations, it is not possible to use a manual proofer balancer for dough relaxation :

-

Too high a temperature in the bakery (high risk of sticking)

-

Pasta that has already had a long pre-fermentation

-

Insufficient space available in the room

-

Budget too limited

For these different reasons, MERAND has designed the EasyLine range of automatic lines. On these lines, the automatic scale is replaced by the WorkBelt® transfer belt with speed variator, or the very small "EasyRest" scale.

Here are some examples of configurations :

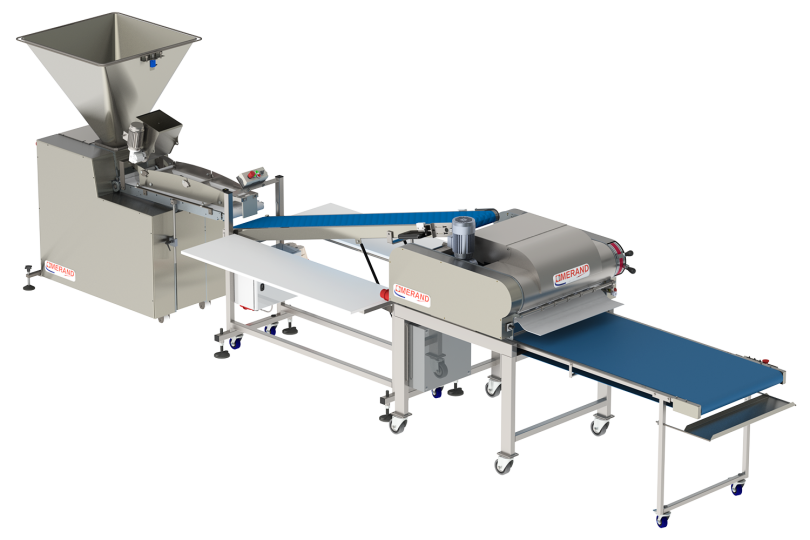

The EasyLine® 1.5 automatic line can produce 1.500 loaves of bread or baguettes per hour, approximately 18. 000 loaves per day. It consists of :

1 Softy® automatic divider with a system for pre-elongating the dough pieces to facilitate subsequent shaping.

2 WorkBelt transfer belt with speed variator to vary the expansion.

3 Shaper Armor allonge+, with a first allonge that can be disengaged according to the type of bread to be shaped.

4 Receiving belt for shaped dough pieces.

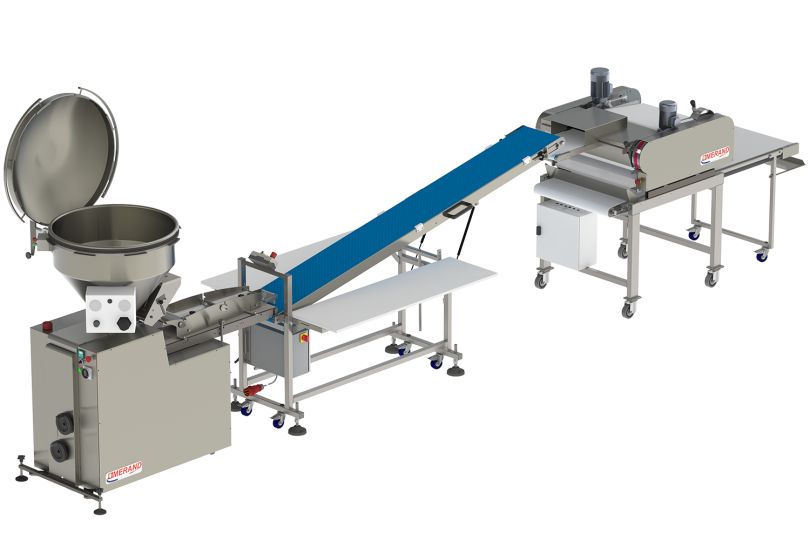

The EasyLine® 1.8 automatic line can produce 1. 800 loaves of bread or baguettes per hour, approximately 20. 000 loaves per day. It is composed of :

1 Softy® automatic divider with a system for pre-elongating the dough pieces to facilitate subsequent shaping.

2 TopCad transfer belt with speed control to vary the expansion

3 3Form semi-industrial shaper, with progressive 3-stage stretching to optimise extantion and consistency

4 Conveyor belt for receiving the shaped dough pieces or for an automatic deposit on nets.

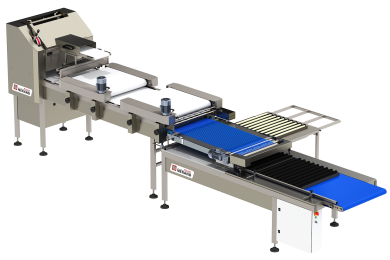

The EasyLine® 2.5 automatic line can produce 2500 loaves or baguettes/hour, approximately 50. 000 loaves per day. It consists of :

1 Softy® automatic divider with a system for pre-elongating the dough pieces to facilitate subsequent shaping.

2 Transfer belt with speed variator to vary the expansion

3 Proform industrial shaper with the exclusive C2A shaping system.

4 Automatic threading machine

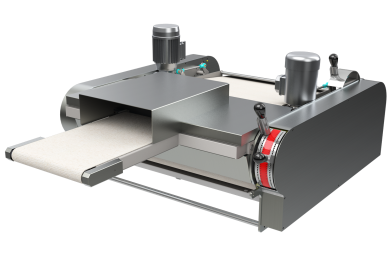

Various accessories can be added to the EasyLine® automatic, such as the Pointop® system for baguettes with pointed ends, or the calibration of large dough pieces for the production of moulded breads, sandwich loaves, sticks, large loaves, etc....

-

Easy to use

-

Reliability

-

Time saving

-

Simplified maintenance and servicing

-

Higher quality and consistency than by hand