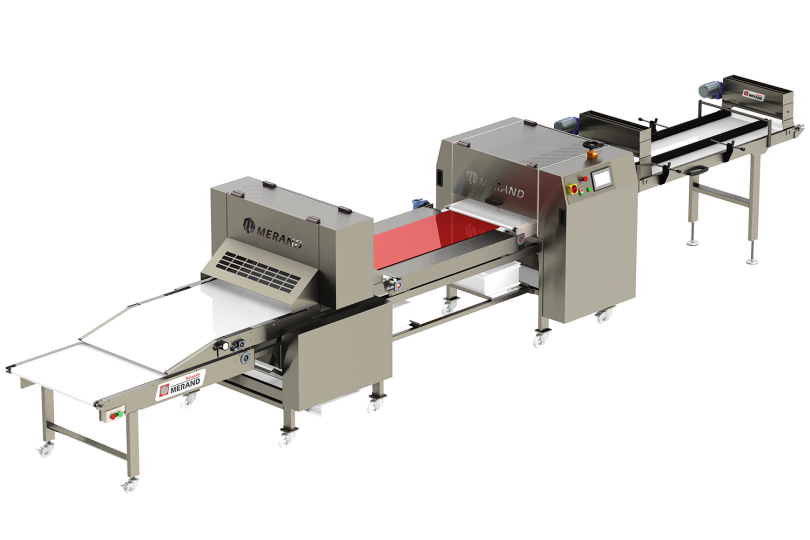

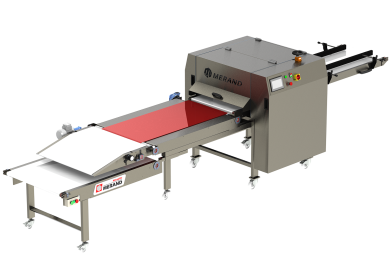

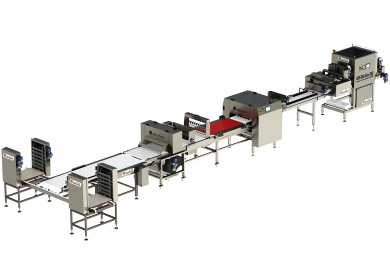

AquaPan 7000 & AquaPan 7500 with continuous feed system

The AquaPan® 7000 and 7500 models are equipped with an automatic system for depositing the dough pieces on the supports (boards, nets...).

This machine has been designed for all types of bread : ciabatta, rustic bread, traditional bread and others; Ideal for the production of highly hydrated dough (up to 90% hydration). Dough trays are poured onto the feeding belt. Stress-free rolling thanks to the MultiRoller is the basic principle of the AquaPan®.

Once the dough has been calibrated to your specifications, it is cut into dough strips by a set of discs. The strips of dough are then cut to the desired size using a guillotine. The guillotine can be either straight or angled. The guillotine is independent of the laminating system and the cutting disc system.

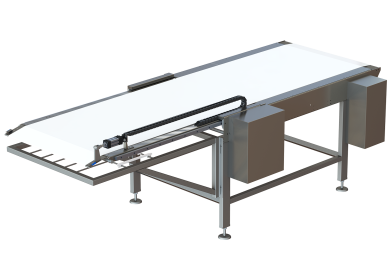

The separator of these strips are placed on a transfer table. The offcuts are automatically removed and fall into a tray under the table. Automatic depositing of the products on nets (manual feeding of the nets under the depositing table).

Accessories Included

- Roller with 4 cutting discs

- Roller with 10 cutting discs

- Guillotine with 4 inclined blades for rustic breads

- Guillotine with 10 inclined blades for rustic breads

- Straight guillotine for ciabatta

- 6 plastic trays 600mm x 400mm x 170mm

|

AquaPan® 7000 |

AquaPan® 7500 |

|

|

Capacity |

250 à 500kg |

350 à 600kg |

|

Entrance belt |

1500 x 600 folding |

2400 x 650 folding |

|

Outfeed belt |

800mm wide |

800mm wide |

|

Lenght Working position |

6 500 mm |

7 100 mm |

|

Working height |

985 / 770 mm |

985 / 770 mm |

|

Adjustable side guides |

included |

included |

|

Trimming management |

automatic |

automatic |

|

Satelitte Multi Roller No Stress (MRNS) |

8 rolls |

8 rolls |

|

Guillotine |

electric |

electric |

|

Rollers with brakes |

included |

included |

|

Memorization of 20 recipes |

20 recipes |

20 recipes |

|

Touch control interface |

touch screen |

touch screen |

|

Type of application on net |

auto |

auto |

|

Telescopic deposit table with sensor |

yes |

yes |

|

Flour collector (stainless steel) |

yes |

yes |

|

Longitudinal cutting station |

yes |

yes |

|

10 plastic bins |

600 x 400mm |

600 x 400mm |

|

bar + discs |

5 bars + 7 et 11 discs |

6 bars + 7 et 11 discs |

|

Mitre cutting die |

6 / 10 rows |

6 / 10 rows |

|

Straight cutting die |

included |

included |

|

Electrical connection for seed application and humidification |

included |

|

|

Oscillating side guides |

option |

option |

|

Flouring machine |

yes |

included |

|

Retractable belt |

yes |

yes |

|

Cross laminating system |

yes |

yes |

|

Humidifier + seeder |

yes |

yes |

|

Net storage / destocker |

yes |

yes |

|

Cutting of round dough pieces |

yes |

yes |

|

Automatic feeding |

yes |

yes |

|

Shavings collector |

yes |

yes |

|

|

Accessories included |

|

|

Possible options |