This operation consists in letting the dough rest between dividing and shaping. The relaxation will favour the elongation in the shaper without the need to stress the dough too much during the rolling and elongation in the machine. The dough will retain all its properties even better. The resting time is variable. It depends on the products to be baked, the nature of the dough, the type of production (fresh/frozen, etc.), the ambient temperature, the shape of the dough pieces after division, etc.

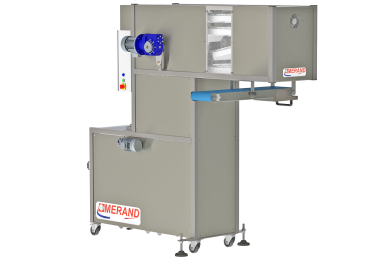

- The semi-automatic intermediate proofers offer the same advantages as manual proofer, but unlike the latter, after proofing, the dough pieces go automatically into the moulder.

- The automatic intermediate proofers offer even greater productivity as they are connected to automatic dividing and weighing machines.